CONDENSATE POTS are used to catch and hold condensate. This helps keep manifold orifices clean and free of foreign material. They are located upstream of the instrument and have a bottom drain so that they may be cleaned. The condensate pots are available in a range of materials. Installation can be either vertical or horizontal lines between primary (Flow Meter) and the secondary (transmitter/ gauge) to act as a barrier to the line fluid permitting direct sensing of the flow conditions. Units should be mounted at the same level minimizing possible error that could arise due to unequal head of fluid in the connecting pressure lines. Typical industry applications include: refineries, Power Plants, Chemical and Petrochemical, Steel Plants and other process industries. SEAL POTS (sometimes called condensate pots) are used to allow a liquid seal between the instrument and flowing gases such as steam. Their function is to keep the liquid level constant in the impulse tubes. For example, in boiler liquid level applications the high pressure (HP) side of a differential pressure transmitter is connected to the vapor space on top of the steam drum. Steam condenses in the chamber or seal pot and fills the impulse line with condensate. The seal pot is located to allow the condensate to drain back to the source thus keeping the liquid level constant.

Click Here to Access our Product Gallery for Sample Photos of Condensate Pot

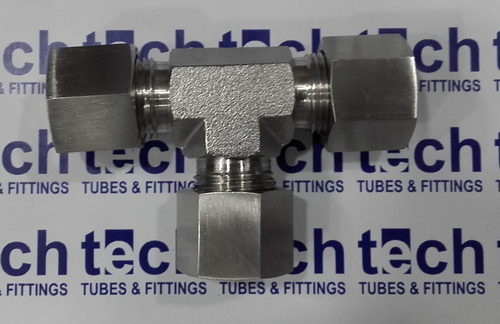

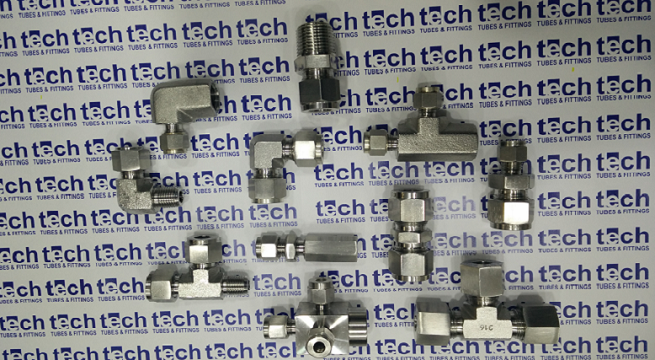

Check our our other Products : High Pressure Instrumentation Valves, High Pressure Tube Fittings, High Pressure Pipe Fittings

Application:

- Refineries

- Power Plant

- Chemical and Petrochemical

- Steel Plants

- Other Process Industries

For any further information or query, please feel free to contact us

Tech Tubes & Fittings deals in a variety of Tube Fittings, Valves, Condensate Pot, Pipe Fittings and Flanges manufactured from High Performance Alloys.

UNS S15500 Tube Fittings, UNS S15500 Instrumentation Tube Fittings, UNS S15500 Ferrule Fittings, UNS S15500 Compression Fittings, UNS S15500 Single Compression Fittings, UNS S15500 Double Compression Fittings, UNS S15500 Single Ferrule Fittings, UNS S15500 Double Ferrule Fittings, UNS S15500 Tube Fittings Manufacturer in India, UNS S15500 Instrumentation Tube Fittings Exporter, High Pressure UNS S15500 Tube Fittings Manufacturer in India, High Pressure UNS S15500 Tube Fittings Exporter,

Monel, Hastelloy, Inconel, Incoloy, SMO254, Nitronic, PH Alloy, AL6XN, Tungsten, Stellite, Sanicro, Tantalum, Molybdenum, Zirconium, Nimonic , Alloy A286, Invar, Alloy 20, Cupronickel Cu Ni 70-30, Brass are the trademarks of their respective companies