Monel Tube Fittings

|  |  |

| MONEL TUBE UNION | MONEL BULKHEAD TUBE UNION | MONEL MALE CONNECTOR (INCH X NPT THREAD) |

|  |  |

| MONEL MALE CONNECTOR (INCH X ISO THREAD) | MONEL MALE CONNECTOR (MM X ISO THREAD) | |

|  |  |

| MONEL FEMALE CONNECTOR (INCH X NPT THREAD) | MONEL FEMALE CONNECTOR (MM X NPT THREAD) | MONEL FEMALE CONNECTOR (INCH X ISO THREAD) |

|  |  |

| MONEL FEMALE CONNECTOR (MM X ISO THREAD) | MONEL UNION ELBOW | MONEL MALE ELBOW (INCH X NPT THREAD) |

|  |  |

| MONEL MALE ELBOW (MM X NPT THREAD) | MONEL FEMALE ELBOW (INCH X NPT THREAD) | MONEL FEMALE ELBOW (MM X NPT THREAD) |

|  |  |

| MONEL UNION TEE | MONEL MALE RUN TEE (INCH X NPT THREAD) | MONEL MALE RUN TEE (MM X NPT THREAD) |

|  |  |

| MONEL BRANCH TEE (INCH X NPT THREAD) | MONEL MALE BRANCH TEE (MM X NPT THREAD) | MONEL FEMALE RUN TEE (INCH X NPT THREAD) |

|  |  |

| MONEL FEMALE RUN TEE (MM X NPT THREAD) | MONEL FEMALE BRANCH TEE (INCH X NPT THREAD) | MONEL BRANCH TEE (MM X NPT THREAD) |

|  |  |

| MONEL UNION CROSS | MONEL PIPE END CLOSURE | MONEL NUT AND FERRULE |

Monel Tube Fittings Monel Ferrule Tube Fittings Monel Double Ferrule Tube Fittings Monel Instrumentation Tube Fittings Monel Compression Tube Fittings

MONEL TUBE FITTINGS, MONEL FERRULE FITTINGS, MONEL INSTRUMENTATION FITTINGS, MONEL FERRULE TUBE FITTINGS MANUFACTURER IN INDIA, MONEL COMPRESSION FITTINGS, MONEL FERRULE FITTINGS, MONEL INSTRUMENTATION TUBE FITTINGS EXPORTER INDIA, MONEL COMPRESSION FITTINGS EXPORTER IN INDIA, MONEL HIGH PRESSURE TUBE FITTINGS INDIA, MONEL SINGLE COMPRESSION TUBE FITTINGS, MONEL DOUBLE COMPRESSION TUBE FITTINGS INDIA.

Manufacturer of ASTM B564 Monel® Tube Fittings, Alloy 400 Monel® Tube Fittings, Alloy K500 Monel® Tube Fittings in Single Ferrule and Double Ferrule Types. ASTM B564 UNS N04400 Tube Fittings also in our scope.

Monel® Ferrule Tube Fittings & ASTM A564 UNS N04400 Tube Fittings by Tech Tubes & Fittings are designed for instrumentation and process applications where leak-tight-0-failure is critical. Tech Tubes & Fittings produces Single Ferrule Type Monel® Tube Fittings and Double Ferrule type Monel® Tube Fittings. Each product is designed as per International norms and quality. These Monel® Tube Fittings can be used in high vibration or pressure applications. Monel® Tube Fittings are exported to more than 24 countries by us.

Most sold Monel® Tube Fittings: Monel® 400 Tube Fittings, Monel® K500 Tube Fittings, Monel® 400 Ferrule Fittings, Monel® K500 Ferrule Fittings. Monel® 400 Single Ferrule Fittings, Monel® Instrumentation Fittings, Monel® Compression Fittings

Details of ASTM B366 UNS N04400 Tube Fittings / Monel® Tube Fittings

TYPE

- Single & Double Ferrules

- Compression Ends, Threaded, Socket Weld and Others.

RANGE

- Tee (Union Tee, Run Tee, Branch Tee)

- Elbow - 45 Deg & 90 Deg (Union Elbow, Connector Elbow)

- Connector (Bulk Head, Straight & Reducing)

- Cap

- Plug

- Union (Bulk Head, Straight & Reducing)

- Cross

- Nut

- Ferrules

- Adapter

- Port Connector

- As per Client Customization / Drawing

SIZE RANGE

- For Metric Tube : 1.6mm to 50mm

- For Imperial Tube : 1/16" to 2"

PRESSURE RANGE

- 100 Bar to 650 Bar

- 1500 Psi to 10000 Psi

|

Alloy Name |

Trade Name |

UNS No. |

Werkstoff No. |

|

Alloy 400 |

Monel® 400 |

N04400 |

2.4360 |

|

Alloy K500 |

Monel® K500 |

N05500 |

2.4375 |

Fast Moving Items

- Monel® 400 Tube Fittings

- Monel® 401 Tube Fittings

- Monel® 404 Tube Fittings

- Monel® K500 Ferrule Fittings

- Monel® R405 Tube Fittings

- Monel® 450 Tube Fittings

- Alloy 400 Ferrule Fittings

- Alloy K500 Ferrule Fittings

- Alloy 450 Tube Fittings

- UNS N04400 Tube Fittings

- UNS N04401 Tube Fittings

- UNS N04404 Tube Fittings

- UNS N05500 Tube Fittings

- UNS N04405 Ferrule Fittings

EXPORTERS TO

- Canada

- USA

- Mexico

- Venezuela

- Chile

- Brazil

- Indonesia

- Malayasia

- Singapore

- Brunei

- Thailand

- Oman

- Qatar

- Bahrain

- Saudi Arabia

- Kuwait

- Jordan

- Greece

- Italy

- Romania

- Austria

- France

- Netherland

- Germany

- UK

- Spain

- Portugal

- Norway

- Finland

Monel® Socket Weld, Threaded & Forged Pipe Fittings

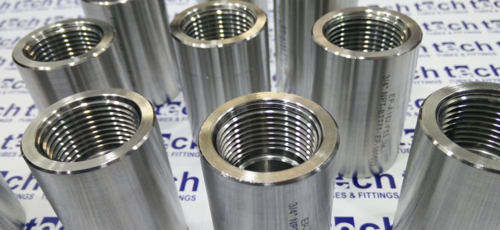

Precision Monel® Pipe Fittings are manufactured by Tech Tube & Fittings in both Monel® Socket Weld Pipe Fittings & Monel® Threaded Pipe Fittings domain. These Monel® Fittings are manufactured as per ASTM, ASME, JIS, BS, IS, DIN, MSS Standards with a variety of threads as per client requirement (NPT, BSP, UNF, Metric etc.,) Monel® Pipe Fittings are manufactured as per client's customization and drawings too. High pressure and Low Pressure fittings both : Monel® Socket Weld Fittings and Monel® Threaded Fittings fall under our domain.

Most Sold Monel® Fittings : Monel® Socket Weld Fittings, Monel® NPT Threaded Fittings, Monel® BSP Threaded Fittings, Monel® 400 Forged Fittings, Monel® B16.11 Fittings, Monel® High Pressure Fittings

TYPE

- Socket Weld

- Threaded (BSP, BSPT, NPT)

RANGE

- Coupling (Full & Half)

- Socket (Full & Half)

- Plug (Hex Head, Square Head, Round Head, Drain)

- Cap

- Elbow (45Deg & 90Deg)

- Street Elbow

- Tee (Run Type & Branch Type)

- Cross

- Union (3 Piece)

- Nipple (Pipe Type & Hex Type)

- Insert

- Bushing

- As per Client Customization / Drawing

SIZE RANGE

- 1/8"NB (6NB) to 4"NB (100NB)

PRESSURE RANGE

- 1500# to 9000#

- 1000 Psi to 15000 Psi

Available Grades

- ASTM Monel® 400

- ASTM Monel® 401

- ASTM Monel® 404

- ASTM Monel® K500

- ASTM Monel® R405

- ASTMMonel® 450

- ASTM B564 Alloy 400

- ASTM B564 Alloy K500

- ASTM B564 Alloy 450

- ASTM B564 UNS N04400

- ASTM B564 UNS N04401

- ASTM B564 UNS N04404

- ASTM B564 UNS N05500

- ASTM B564 UNS N04405

- ASTM B564 UNS N04400

- ASTM B564 UNS N04401

- ASTM B564 UNS N05500

- ASTM B564 UNS N04405

- ASTM B164 UNS N04400

- ASTM B164 UNS N04401

- ASTM B164 UNS N05500

- ASTM B164 UNS N04405

Monel® 400 Tube Fittings

Monel® 400 Tube Fittings, Monel® K500 Tube Fittings, Monel® 400 Tube Fittings, Monel® UNS N04400 Tube Fittings, Monel® N04400 Tube Fittings, Monel® N05500 Tube Fittings, Monel® 400 Is A Monel® Nickel-Copper Alloy, Resistant to Sea Water and Steam at High Temperatures as Well as to Salt and Caustic Solutions. Monel® 400 Is A Nickel-Copper Alloy with Excellent Corrosion Resistance in A Wide Variety of Media. Monel® 400 Male Elbow, Monel® Female Elbow, Monel® Union Elbow, Monel® Union Tee, Monel® Male Run Tee, Monel® Male Branch Tee, Monel® Female Branch Tee, Monel® Female Run Tee, Monel® Male Connector, Monel® Bulkhead Male Connector, Monel® Female Connector, Monel® Bulkhead Female Connector, Monel® Bulkhead Union, Monel® Union Cross, Monel® Ferrule Nut, Monel® Back Ferrule, Monel® Front Ferrule, Monel® Bulkhead Nut Manufacturer In India Monel® 400 Is A Nickel-Copper Monel®, It Is Particularly Resistant To Hydrochloric And Hydrofluoric Acids When They Are De-Aerated. The Alloy Is Slightly Magnetic at Room Temperature. Monel® 400 Is Widely Used the Chemical, Oil & Marine Industries.

Characteristics of Monel® 400 Tube Fittings

Monel® alloy is more resistant to nickel under reducing conditions and more resistant than copper under oxidizing conditions, it does show however better resistance to reducing media than oxidizing.

Good mechanical properties from subzero temperatures up to about 480C. Monel® Good resistance to sulfuric and hydrofluoric acids. Aeration however will result in increased corrosion rates. May be used to handle hydrochloric acid, but the presence of oxidizing salts will greatly accelerate corrosive attack.

Applications of Monel® Tube Fittings

- Sulfuric acid and hydrofluoric acid alkylation plants.

- Feed water and steam generator tubing.

- Pumps and valves used in the manufacture of chlorinated plastics.

- Heat exchangers in a variety of industries.

- Brine heaters, sea water scrubbers in tanker inert gas systems.

- Pickling bat heating coils.

- Cladding for the upper areas of oil refinery crude columns.

- Transfer piping from oil refinery crude columns.

- Propeller and pump shafts.

- Monoethanolamide MEA reboiling tube.

- Oil-well tools, Instruments, Springs, Valve trim, Fasteners,

- Marine propeller shafts

- Marine components

Advantages of ASTM B564 UNS N00400/ASTM B564 UNS N05500 Monel® Tube Fittings

Good Resistance To Acids Such As Hydrofluoric And Sulfuric Acid

Highly Resistant To Alkalis

Malleable

Highly Corrosion Resistant

APPLICATIONS

- Heat Exchangers

- Process Industry

- Control & Instrumentation

- Valves

- Marine

- Chemical Process Industry

- Hydro Carbon Processing

- Oil Refineries etc.,

BENEFITS

- High Durability

- Excellent Mechanical Properties

- Resistance to Sulphuric & Hydrofluoric acids

- Resistance to SSC Cracking

- High Temperature Services

FEATURED PRODUCTS

- ASTM Monel® Tube Fittings /Compression Fittings

- ASTM Monel® Fittings /Compression Fittings

- ASTM Monel® Single Ferrule Fittings /Compression Fittings

- ASTM Monel® Double Ferrule Fittings /Compression Fittings

- ASTM Monel® Ferrule Fittings/Compression Fittings

- ASTM Monel® Forged Pipe Fittings /Compression Fittings

- ASTM Monel® Pipe Fittings /Compression Fittings

- ASTM Monel® WNRTJ Flanges

- ASTM Monel® Orifice Flanges Link

- ASTM Monel® BLRF Flanges

- ASTM Monel® RTJ Flanges

- ASTM Monel® Flanges

- ASTM Monel® SORF Flanges

- ASTM Monel® Valves

- Monel® Manifold Valves

- Monel® Needle Valve

- Monel® Ball Valve

- Monel® Mini Ball Valve

- Monel® 5 Way Manifold Valve

- Monle® 2 Way Manifold Valve

- Monel® 3 Way Manifold Valve

- Monel® Socket Weld Fittings

- Monel® Threaded Fittings /Compression Fittings

- Monel® Screwed Fittings /Compression Fittings

- Monel® NPT Fittings /Compression Fittings

- Monel® BSPT Fittings /Compression Fittings

- Monel® BSP Fittings /Compression Fittings

- Monel® High Pressure Fittings /Compression Fittings

- Monel® Threaded Forged Fittings /Compression Fittings

Monel® Instrumentation Valves

Tech Tubes & Fittings manufactures a variety of high pressure & low pressure Monel® Needle Valves, Monel® Ball Valves, Monel® 2-Way Manifold Valves, Monel® 3-Way Manifold Valves, Monel® 5-Way Manifold Valves, Monel® Check Valves. These valves can sustain high temperatures, high pressures, and low pressures. Pressure Range: 500 Psi to 10000 Psi (690 Bar). Temperature Range : -73Deg. Celcius to 510Deg. Celcius

Most sold Monel® Valves: Monel® 400 High Pressure Needle Valves, Monel® K500 Needle Valves, Monel® 400 Ball Valves, Monel® K500 Ball Valves, Monel® 400 Manifold Valves, Monel® 400 Condensate Pots, Monel® 400 High Pressure Valves, Monel® 400 Check Valves.

TYPE

- Forged & Barstock

RANGE

- Monel® Ball Valve

- Monel® Needle Valve

- Monel® Manifold Valve

- Monel® Plug Valve

- Monel® Gauge Valve

- Monel® Check Valve

- Monel® Pressure Relief Valve (PRV)

SIZE RANGE

- For Tube Ends: 1.6mm to 50mm

- For Threaded Ends 1/16" to 2"

PRESSURE RANGE

- 100 Bar to 650 Bar

- 1500 Psi to 10000 Psi

Chemical Composition, %

| C | Mn | S | Si | Ni | Cu | Fe |

|---|---|---|---|---|---|---|

| .30 max | 2.00 max | .024 max | .50 max | 63.0 min | 28.0-34.0 | 2.50 max |

Mechanical Properties

Typical room temperature Tensile Properties of Annealed Material

|

Product Form |

Condition | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) | Hardness (HRB) |

|---|---|---|---|---|---|

| Rod & Bar | Annealed | 75-90 | 25-50 | 60-35 | 60-80 |

| Rod & Bar | Cold-Drawn Stress Relieved | 84-120 | 55-100 | 40-22 | 85-20 HRC |

| Plate | Annealed | 70-85 | 28-50 | 50-35 | 60-76 |

| Sheet | Annealed | 70-85 | 30-45 | 45-35 | 65-80 |

| Tube & Pipe Seamless | Annealed | 70-85 | 25-45 | 50-35 | 75 max * |

PARTIAL LIST OF EXECUTED ORDERS

|

Year |

Country |

Field |

Product |

|

2017 |

Nigeria |

Chemical | |

|

2017 |

South Africa |

Gas |

UNS N04400 Male Connectors 1/2”OD X 1/2"NPT UNS N04400 Union 1/2”OD X 1/2"OD |

|

2017 |

Italy |

Oil |

ASTM B564 Monel Tube Fittings |

|

2017 |

Kazakhstan |

Oil |

ASTM B564 Alloy K500 Double Compression Fittings |

|

2017 |

Algeria |

Oil |

ASTM B564 UNS N04400 Ferrules |

|

2017 |

USA |

Oil |

ASTM B564 UNS N04400 Needle Valves |

|

2017 |

Egypt |

Power |

ASTM B564 Monel Manifold Valves, ASTM B564 Monel Union Tee 1/2"OD |

|

2017 |

Norway |

Fire |

ASTM B564 Monel B16.11 Fittings |

|

2017 |

USA |

Oil |

ASTM B564 UNS N04400 Forged Fittings |

|

2017 |

South Africa |

Gas |

UNS N04405 Male Connectors 1/2”OD X 1/4"NPT UNS N04405 Union 1/2”OD X 1/4"OD |

|

2017 |

South Africa |

Gas |

UNS N04400 Needle Valves 1/2”OD X 1/2"OD UNS N04400 Ball Valves 1/2”NPTF X 1/2"NPTF |

|

2017 |

Singapore |

Ship Building |

UNS N05500 Nut & Double Ferrules 1”OD |

|

2017 |

Nigeria |

Oil |

Alloy 400 Needle Valve 1/4"OD 6000PSI |

|

2017 |

Kazakhstan |

Oil |

ASTM B564 Alloy K500 Double Compression Fittings |

|

2017 |

Greece |

Power |

Monel Double Compression Fittings 1/8”OD |

|

2017 |

Oman |

Oil |

Alloy K500 Double Compression Ferrules 3/4"OD |

|

2017 |

Kuwait |

Oil |

Alloy 400 Female Connector 1/2"OD X 1/2"NPT |

|

2017 |

Algeria |

Oil |

UNS N04400 Ferrules, UNS N05500 Ferrules |

|

2017 |

Oman |

Oil |

Monel Union 1/2"OD 3000PSI |

|

2017 |

UAE |

Oil |

Alloy 400 Nuts & Ferrules 1/16”OD |

|

2017 |

Mexico |

Chemical |

Monel Bulk Head Union 1”OD X 1”OD |

|

2017 |

Saudi Arabia |

Oil |

Alloy 400 Male Connector 1/4"OD X 1”BSP |

|

2017 |

Mexico |

Power |

Monel Bulk Head Union 1/2”OD X 1/2”OD Monel Bulk Head Union 1/4”OD X 1/4”OD Monel Bulk Head Union 1”OD X 1”OD |

|

2017 |

Mexico |

Power |

Monel Double Ferrules 1/2”OD, 1/4”OD |

|

2017 |

Qatar |

Gas |

Alloy K500 Male Connector 8mm OD X 1/4"NPT |

|

2016 |

Indonesia |

Instrumentation |

ASTM B564 |

|

2016 |

Singapore |

Ship Building |

Alloy 400 Tube Fittings, UNS N04400 Male Connectors 12mm OD X 1/4"NPT, UNS N04400 Tube Cap 12mm OD |

|

2016 |

Singapore |

Oil |

ASTM B564 Alloy K500 3000PSI Union Tee 5/8”OD |

|

2016 |

South Africa |

Gas |

ASTM B564 Alloy 400 Forged Elbow 3000# 1/2" Socket Weld ASTM B564 Alloy 400 Forged Tee 3000# 1/2" Socket Weld |

|

2016 |

Nigeria |

Power |

ASTM B564 Monel Hex Head Plug 1/2" |

|

2016 |

USA |

Power |

ASTM B564 Monel Manifold Valves and Needle Valves |

|

2016 |

Norway |

Fire |

Alloy 450 90Deg Male Elbow 6mm OD X 1/2"NPT |

|

2016 |

France |

Power |

Monel End Cap |

|

2016 |

Brazil |

Chemical |

Monel Tube Fittings – Multiple Sizes |

|

2016 |

Mexico |

Power |

Alloy 400 Socket Weld Coupling |

|

2016 |

Malaysia |

Oil |

ASTM B564 Alloy 400 Flange 4”NB Sch 160 WNRF 300# ASTM B564 Alloy 400 Flange 6”NB Sch 160 WNRF 300# ASTM B564 Alloy 400 Flange 5”NB Sch 160 WNRF 300# ASTM B564 Alloy 400 Flange 1/2”NB Sch 160 WNRF 300# |

|

2016 |

Yemen |

Oil |

ASTM B564 UNS N05500 Adapters B16.11 |

|

2016 |

Ireland |

Power |

ASTM B564 UNS N04400 Flanges B16.5 |

|

2016 |

South Africa |

Gas |

ASTM B564 Alloy 400 Forged Cross B16.11 3000# 1/2" NPT ASTM B564 Alloy 400 Forged Union B16.11 3000# 1/2" NPT |

|

2016 |

Egypt |

Power |

Alloy 400 Check Valve 1/2"OD |

|

2015 |

Estonia |

Instrumentation |

Alloy K500 Male Run Tee 1/2"OD X 1/2"OD X 1/2"NPT Run |

|

2015 |

Finland |

Instrumentation |

ASTM B564 Compression Fittings - Multiple Size |

|

2015 |

Serbia |

Chemical |

Alloy 400 Tube Connectors 10mm OD X 1/4"NPT |

|

2015 |

Venezuala |

Oil & Gas |

Alloy K500 5 Way T Type Manifold Valves |

|

2015 |

Bahrain |

Oil |

Alloy 400 High Pressure Ball Valve 1”NPT |

|

2015 |

Bahrain |

Oil |

ASTM B564 Monel Tube Fittings |

|

2015 |

Italy |

Chemical |

ASTM B564 UNS N05500 B16.11 3 Piece Union 6000# 1" NPT ASTM B564 UNS N05500 B16.11 Elboe 6000# 1" NPT |

|

2015 |

Portugal |

Chemical |

ASTM B564 Monel Double Ferrule Tube Fittings |

|

2015 |

USA |

Chemical |

ASTM B564 Monel Single Ferrule Tube Fittings |

|

2015 |

Singapore |

Chemical |

ASTM B564 Monel B16.48 Spectacle Blind Flanges |

|

2015 |

Kuwait |

Power |

ASTM B564 Monel B16.5 Forged Flanges |

|

2015 |

Portugal |

Chemical |

ASTM B564 UNS N04405 Single Ferrule Tube Fittings |

|

2015 |

Brazil |

Chemical |

ASTM B564 Monel B16.36 Orifice Flanges |

|

2015 |

Turkey |

Power |

ASTM B564 Monel B16.11 Forged Pipe Fittings |

DETAILS

Alloy 400 | ASTM B 164 | QQ N 281 | DIN 17752 | ISO 15156 | BS3072NA13 | AMS 4544 |

W.Nr 2.4360 | UNS N04400 | NACE MR-01-75

Alloy 400 Tube Fittings, Alloy 400 Pipe Fittings, Alloy 400 Flanges, Alloy 400 Manifold Valves, Alloy 400 Needle Valves, Alloy 400 Ball Valves

Ni 66.5 Cu 31 Fe 2.5 Mn 2.0 C 0.3 Si 0.5 S 0.024

High Performance Alloys stocks and produces Alloy 400 in this grade in the following forms: Bar, square bar, wire spool, wire cuts, loose coil, sheet/plate, tube, pipe, flange. Request quote on this grade.

Overview

Alloy 400 is a Nickel-Copper alloy, resistant to sea water and steam at high temperatures as well as to salt and caustic solutions. Alloy 400 is a nickel-copper alloy with excellent corrosion resistance in a wide variety of media. Alloy 400 is characterized by good general corrosion resistance, good weldability and moderate to high strength. The alloy has been used in a variety of applications. It has excellent resistance to rapidly flowing brackish water or seawater. It is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. The alloy is slightly magnetic at room temperature. Alloy 400 is widely used in the chemical, oil and marine industries.

Characteristics

- Corrosion resistance in an extensive range of marine and chemical environments. From pure water to nonoxidizing mineral acids, salts and alkalis.

- This alloy is more resistant to nickel under reducing conditions and more resistant than copper under oxidizing conditions, it does show however better resistance to reducing media than oxidizing.

- Good mechanical properties from subzero temperatures up to about 480C.

- Good resistance to sulfuric and hydrofluoric acids. Aeration however will result in increased corrosion rates. May be used to handle hydrochloric acid, but the presence of oxidizing salts will greatly accelerate corrosive attack.

- Resistance to neutral, alkaline and acid salts is shown, but poor resistance is found with oxidizing acid salts such as ferric chloride.

- Excellent resistance to chloride ion stress corrosion cracking.

Applications

- Feed water and steam generator tubing.

- Brine heaters, sea water scrubbers in tanker inert gas systems.

- Sulfuric acid and hydrofluoric acid alkylation plants.

- Pickling bat heating coils.

- Heat exchangers in a variety of industries.

- Transfer piping from oil refinery crude columns.

- Plant for the refining of uranium and isotope separation in the production of nuclear fuel.

- Pumps and valves used in the manufacture of perchlorethylene, chlorinated plastics.

- Monoethanolamine (MEA) reboiling tube.

- Cladding for the upper areas of oil refinery crude columns.

- Propeller and pump shafts.

Specifications

Bar – ASTM B 164, QQ N 281, DIN 17752, AMS 4675

Sheet – ASTM B 127, QQ N 281, BS3072NA13, AMS 4544, DIN 17750

Plate – ASTM B 127, QQN 281, BS3072NA13, AMS 4544, DIN 17750

Strip – BS3073NA13, ASTM B127, AMS 4544, DIN 17750

Pipe – ASTM B 185

Tube – ASTM B165, AMS 4574, AMS 4575

Forging – ASTM B564, DIN 17752, AMS 4675

Others – W.Nr 2.4360, UNS N04400, NACE MR-01-75, Wire AMS 4730 Alloy 400 (tradename), ISO 15156

Alloy K-500 | BS3072 NA18 | QQ-N-286 | DIN 17750 | ISO 6208 | ASTM B 865 | UNS N05500 | Werkstoff Nr. 2.4375 | MIL-N-24549 | NACE MR-01-75

Alloy K500 Tube Fittings, Alloy K500 Pipe Fittings, Alloy K500 Flanges, Alloy K500 Manifold Valves, Alloy K500 Needle Valves, Alloy K500 Ball Valves

Ni 63.0 Cu 29.5 Al 2.7, Ti 0.6 C 0.18 Fe 2.0 Mn 1.5 Si 0.50 S 0.010

High Performance Alloys stocks and produces ALLOY K500 in this grade in the following forms: Bar, square bar, fasteners. Request quote on this grade.

Overview

ALLOY K500 is a age-hardenable Nickel-Copper alloy which combines the corrosion resistance of Alloy 400 with high strength corrosion fatigue and erosion resistance. ALLOY K500 is a nickel-copper alloy, precipitation hardenable through additions of aluminum and titanium. ALLOY K500 retains the excellent corrosion resistant characteristics of 400 and has enhanced strength and hardness after precipitation hardening when compared with 400. Alloy K500 has approximately three (3) times the yield strength and double the tensile strength when compared with 400. ALLOY K500 can be further strengthened by cold working before the precipitation hardening.

Characteristics

- Excellent mechanical properties from sub-zero temperatures up to about 480C.

- Corrosion resistance in an extensive range of marine and chemical environments. From pure water to non-oxidising mineral acids, salts and alkalis.

Applications

- Propeller and pump shafts.

- Pumps and valves used in the manufacture of perchlorethylene, chlorinated plastics.

Typical application for ALLOY K500 which takes advantage of high strength and corrosion resistance are pump shafts, impellers, propeller shafts, valve components for ships and offshore drilling towers, bolting, oil well drill collars and instrumentation components for oil and gas production. It is particularly well suited for centrifugal pumps in the marine industry because of its high strength and low corrosion rates in high-velocity seawater. ALLOY K500 is non-magnetic. ALLOY K500 should be annealed when welded and the weldment then stress relieved before aging. High Performance Alloys, Inc. stocks Alloy K500 in a range of sizes including 3/8″-2-1/2″ diameter cold drawn, annealed and aged, and 2-3/4″-10″ diameter hot finished and aged. Material can be supplied in random lengths, cut to order or machined to your specifications. Machining includes drilling, turning, tapping, threading, CNC shapes, flanges and more.

Specifications

|

Form |

Standard |

|

Metal Type |

UNS N05500 |

|

Bar |

ASTM B865 QQ-N-286 |

|

Wire |

AMS4676 |

|

Sheet |

ASTM B865 QQ-N-286 |

|

Plate |

ASTM B865 QQ-N-286 |

|

Fitting | |

|

Forging |

QQ-N-286 Din 17754 |

|

Weld Wire |

FM 60 ERNiCu-7 |

|

Weld Electrode |

FM 190 ENiCu-7 Din 17753 |

|

Din |

2.4375 |

Machining

Nickel & cobalt base corrosion, temperature and wear-resistant alloys, such as ALLOY K500, are classified as moderate to difficult when machining, however, it should be emphasized that these alloys can be machined using conventional production methods at satisfactory rates. During machining these alloys work harden rapidly, generate high heat during cutting, weld to the cutting tool surface and offer high resistance to metal removal because of their high shear strengths. The following are key points which should be considered during machining operations:

- Capacity – Machine should be rigid and overpowered as much as possible. RIGIDITY – Work piece and tool should be held rigid. Minimize tool overhang. TOOL SHARPNESS – Make sure tools are sharp at all times. Change to sharpened tools at regular intervals rather than out of necessity. A 0.015 inch wear land is considered a dull tool.

- Tools – Use positive rake angle tools for most machining operations. Negative rake angle tools can be considered for intermittent cuts and heavy stock removal. Carbide-tipped tools are suggested for most applications. High speed tools can be used, with lower production rates, and are often recommended for intermittent cuts. POSITIVE CUTS – Use heavy, constant, feeds to maintain positive cutting action. If feed slows and the tool dwells in the cut, work hardening occurs, tool life deteriorates and close tolerances are impossible.

- Lubrication – lubricants are desirable, soluble oils are recommended especially when using carbide tooling. Detailed machining parameters are presented Tables 16 and17. General plasma cutting recommendations are presented.

RECOMMENDED TOOL TYPES AND MACHINING CONDITIONS

- Operations – Carbide Tools

- Roughing, with severe interruption – Turning or Facing C-2 and C-3 grade: Negative rake square insert, 45 degree SCEA1, 1/32 in. nose radius. Tool holder: 5 degree neg. back rake, 5 degree neg. side rake. Speed: 30-50 sfm, 0.004-0.008 in. feed, 0.150 in depth of cut. Dry2, oil3, or water-base coolant4.

- Normal roughing – Turning or Facing C-2 or C-3 grade: Negative rate square insert, 45 degree SCEA, 1/32 in nose radius. Tool holder: 5 degree neg. back rake, 5 degree neg. side rake. Speed: 90 sfm depending on rigidity of set up, 0.010 in. feed, 0.150 in. depth of cut. Dry, oil, or water-base coolant.

- Finishing – Turning or Facing C-2 or C-3 grade: Positive rake square insert, if possible, 45 degree SCEA, 1/32 in. nose radius. Tool holder: 5 degree pos. back rake, 5 degree pos. side rake. Speed: 95-110 sfm, 0.005-0.007 in. feed, 0.040 in. depth of cut. Dry or water-base coolant.

- Rough Boring – C-2 or C-3 grade: If insert type boring bar, use standard positive rake tools with largest possible SCEA and 1/16 in. nose radius. If brazed tool bar, grind 0 degree back rake, 10 degree pos. side rake, 1/32 in. nose radius and largest possible SCEA. Speed: 70 sfm depending on the rigidity of setup, 0.005-0.008 in. feed, 1/8 in. depth of cut. Dry, oil or water-base coolant.

- Finish Boring – C-2 or C-3 grade: Use standard positive rake tools on insert type bars. Grind brazed tools as for finish turning and facing except back rake may be best at 0 degrees. Speed: 95-110 sfm, 0.002-0.004 in feed. Water-base coolant.

- Facing Milling – Carbide not generally successful, C- grade may work. Use positive axial and radial rake, 45 degree corner angle, 10 degree relief angle. Speed: 50-60 sfm. Feed: 0.005-0.008 in. Oil or waterbase coolants will reduce thermal shock damage of carbide cutter teeth.

- End Milling – Not recommended , but C-2 grades may be successful on good setups. Use positive rake. Speed: 50-60 sfm. Feed: Same as high speed steel. Oil or water-base coolants will reduce thermal shock damage.

- Drilling – C-2 grade not recommended, but tipped drills may be successful on rigid setup if no great depth. The web must thinned to reduce thrust. Use 135 degree included angle on point. Gun drill can be used. Speed: 50 sfm. Oil or water-base coolant. Coolant-feed carbide tipped drills may be economical in some setups.

- Reaming – C-2 or C-3 grade: Tipped reamers recommended, solid carbide reamers require vary good setup. Tool geometry same as high speed steel. Speed: 50 sfm. Feed: Same as high speed steel.

- Tapping – Not recommended, machine threads, or roll-form them.

- Electrical Discharge Machining – The alloys can be easily cut using any conventional electrical discharge machining system (EDM) or wire (EDM).

Note :-

1. Scea Side cutting edge angle or lead angle of the tool.

2. At any point where dry cutting is recommended, an air jet directed on the tool may provide substantial tool life increases. A water-base coolant mist may also be effective.

3. Oil coolant should be premium quality, sulfochlorinated oil with extreme pressure additives. A viscosity at 100 degrees F from 50 to 125 SSU.

4. Water base coolant should be premium quality, sulfochlorinated water soluble oil or chemical emulsion with extreme pressure additives. Dilute with water to make 15:1 mix. Water-base coolant may cause chipping and rapid failure of carbide tools in interrupted cuts.

5. M-40 series High Speed Steels include M-41 , M-42, M-43, M-44, M-45 and M-46 at the time of writing. Others may be added and should be equally suitable.

6. Oil coolant should be a premium quality, sulfochlorinated oil with extreme pressure additives. A viscosity at 100 degree F from 50 to 125 SSU.

7. Water-base coolant should be premium quality, sulfochlorinated water soluble oil or chemical emulsion with extreme pressure additives. Dilute with water to make 15:1 mix.

Specifications

Sheet – BS3072 NA18, QQ-N-286, DIN 17750, ISO 6208

Plate – BS3072 NA18, QQ-N-286, DIN 17750, ISO 6208

Strip – BS3072 NA18, QQ-N-286, DIN 17750, ISO 6208

Bar – AMS 4676, BS3076 NA18, ASTM B 865, DIN 17752, QQ-N-286, ISO 9723

Rod – AMS 4676, ISO 6208, ASTM B 865, DIN 17752, QQ-N-286

Wire – BS3076, NA18, DIN 17753, QQ-N-286, ISO 9724

Forging – DIN 17754, QQ-N-286, ISO 9725

Other – UNS N05500, BS6076 NA13, Trade name Alloy® Alloy K-500, Werkstoff Nr. 2.4375, MIL-N-24549, NACE MR-01-75

Monel Tube Fittings

Monel 400 is a wrought corrosion-resistant alloy.

Monel 400 also known as Alloy 400 is an alloy that is resistant to corrosion.

The main advantage of using this Alloy (400) is that is does not necessarily require solution heat treatment process after performing welding on it.

The Alloy 400 itself resists the formation of grain boundary precipitate which degrades corrosion resistance.

Monel Tube Fittings are well known for easily machinability, although the alloy is hard when compared to Mild Steel and Stainless Steel. Alloy 400 can be cold worked in all conventional methods. The material can also be forged by conventional means, can be hot formed as well.

Applications

Monel Tube Fittings are used due it its excellent Resistance & Strength. Useful in Marine Applications, Widely used in Pumps, Valves & Shafts. Very reliable in industries such as hydro-carbon and chemical processing. Also used Oil and Gas, Sea-Water Eqpt, Heat Exchangers, Generation of Power, Petrochemical Plants and process industry.

Pressure Rating of Monel Tube Fittings aka Monel Ferrule Fittings as per NPT/ISO – ASME B31.3 is pas per the below chart.

NPT/ISO PIPE SIZE IN. MONEL 400

MALE FEMALE

PSIG (BAR) PSIG (BAR)

1/16 11 000 (757) 6 700 (461)

1/8 10 000 (689) 6 500 (447)

1/4 8 000 (551) 6 600 (454)

3/8 7 800 (537) 5 300 (365)

1/2 7 700 (530) 4 900 (337)

3/4 7 300 (502) 4 600 (316)

1 5 300 (365) 4 400 (303)

1 1/4 6 000 (413) 5 000 (344)

1 1/2 5 000 (344) 4 600 (316)

2 3 900 (268) 3 900 (268)

What are the Features of Monel Tube Fittings:

What are the Features of Monel Tube Fittings:

1. Monel Tube Fittings are highly resistant to alkaline and acidic salts

2. Strongly resistant to Sulphuric Acid and Hydrofluoric Acid

3. The mechanical and chemical properties are better than other materials

4. Monel Tube Fittings provide great resistance to Chloride in SCC (Stress Corrosion Cracking)

5. Easily weldable and Solerable

Standard Configurations Of Monel Alloy400 Ferrule Fittings

1. Tube to Tube – Union Tee, Union Bulk Head, Union Straight, Union Elbow, Tube Union, Union Cross

2. Tube to Male – Male Tee, Male Elbow, Male Connector, Male Cross, Male Bulkhead Connector, Male Run Tee, Male Branch Tee

3. Female Connector – Female Tee, Female Elbow, Male Connector, Female Cross, Female Bulkhead Connector, Female Run Tee, Female Branch Tee

4. Tube Closure – End Cap, Plug

6. Ferrule Set & Nut

Quality Control for Monel Tube Fittings

Quality Control for Monel Tube Fittings

As a manufacturer of Monel Tube Fittings, Tech Tubes & Fittings is backed by ISO 9001: 2008. Most of the Monel Tube Fittings are supplied with a default one year product replacement warranty subject to workmanship defects.

Our Monel Tube Fittings are tested in house for any defects regarding quality / workmanship or manufacturing. If the pressure range is high and if the client needs us to hydrotest the fittings we do the same as well.

Not even a single piece of fitting leaves our premises without a Visual, Gauge, Dimensional inspection and a thorough inspection is done to check if the Monel Tube Fittings match with client Order.

Monel Tube Fittings are supplied with material test certificate as per International Standards mainly EN 10204 3.1

We also provide NACE approved material for all the grades including these Alloy 400, Alloy C22 etc.,

Identification of Brand

All Monel Tube Fittings are manufactured and marked with our registered brand Tactlok that stands for a Tactful seal. Our aim is to provide world class quality and material. We are technology driven and a robust company.

The Fittings are marked with Tactlok-Size-Material-Grade-Heat Number to an extent of 100% for 100% material traceability. The materials are 100% traceable and there is a strict match to ensure authenticity of our brand not being duplicated by others.

Tech Tubes & Fittings is leading Manufacturer of Monel 400 Fittings which include Alloy 400 Tube Fittings of both Single and Double Ferrule type.

Our Tube Fittings are manufactured subject to a smooth-impeccable suface finish mostly coated with Nickel or bright. Monel Tube Fittings are a manufactured in a way to sustain high corrosion, stress and temperature.

These Monel Tube Fittings are used and known for its great resistance in huge variety of chemical process, oxidizer, chloride environment, chlorine, acetic acid, sea water etc., The content of molybdenum and nickel is high in this alloy which makes these Monel Compression Tube Fittings resistance to pitting, crevice and corrosion in highly reactive environments. Tech Tube & Fittings exports Monel tube fittings to various countries.

This alloy includes various grades like Monel Werkstoff Nr 2.4360 Tube Fittings, Alloy 400 Tube Fittings, Alloy K500 Tube Fittings, Monel 400 Tube Fittings, 400 Tube Fittings which are used in various industries like chemical process, process industry, refineries, petrochemicals.

Monel Tube Fittings Specification

Monel Tube Fittings Specification

Specifications: ASTM B564, ASME SB564

Size: 1mm OD to 50mm OD

Or 1/16”OD to 2”OD

Grades: Monel 400, K500 Tube Fittings

Pressure: Upto 12000PSI

MONEL 400 TUBE FITTINGS

MONEL 400 TUBE FITTINGS

Unmatched Performance and Durability: Exploring Monel 400 Tube Fittings for Demanding Applications

Introduction: Monel 400 tube fittings are highly regarded for their exceptional performance and durability in challenging environments. Whether you operate in marine, chemical, or oil and gas industries, understanding the benefits and applications of Monel 400 tube fittings is essential. In this comprehensive guide, we will delve into the world of Monel 400 tube fittings, exploring their properties, advantages, applications, and key considerations.

Section 1: Introduction to Monel 400 Tube Fittings Monel 400 tube fittings are precision-engineered components designed to establish secure connections and maintain the integrity of fluid and gas transfer systems. These fittings are made from Monel 400, a nickel-copper alloy known for its excellent resistance to corrosion, especially in marine environments.

Section 2: Properties of Monel 400 Monel 400 exhibits remarkable properties that make it suitable for demanding applications. Some key properties include:

- Corrosion Resistance: Monel 400 offers excellent resistance to various corrosive environments, including seawater, sulfuric acid, hydrofluoric acid, and alkalis.

- High Strength and Toughness: It possesses excellent mechanical properties, including high tensile strength and good impact resistance.

- Temperature Resistance: Monel 400 maintains its mechanical properties at both high and low temperatures, making it suitable for a wide temperature range.

- Non-Magnetic: Monel 400 is non-magnetic, making it ideal for applications where magnetic interference is a concern.

Section 3: Advantages of Monel 400 Tube Fittings

- Superior Corrosion Resistance: Monel 400 tube fittings provide outstanding resistance to corrosive environments, ensuring long-lasting performance and system integrity.

- Excellent Strength and Durability: They are known for their high tensile strength and toughness, providing reliable performance even in harsh conditions.

- Resistance to Erosion and Fouling: Monel 400 resists erosion and fouling, making it suitable for applications where fluid flow is critical.

- Versatility in Applications: Monel 400 tube fittings find use in marine, chemical processing, oil and gas, and desalination plants, among other industries.

Section 4: Applications of Monel 400 Tube Fittings Monel 400 tube fittings are extensively used in various industries, including:

- Marine and Offshore: Shipbuilding, offshore platforms, and seawater applications.

- Chemical Processing: Handling corrosive chemicals, acids, and alkalis.

- Oil and Gas: Refineries, pipelines, and petrochemical plants.

- Desalination: Reverse osmosis systems and saltwater treatment facilities.

- Aerospace: Fuel systems and hydraulic applications.

Section 5: Key Considerations for Monel 400 Tube Fittings When selecting Monel 400 tube fittings, consider the following factors:

- Compatibility: Ensure compatibility with the specific corrosive media and environmental conditions of your application.

- Size and Configuration: Choose the appropriate fitting size and configuration based on your system requirements.

- Quality and Certification: Source fittings from reputable manufacturers with proper certifications and adherence to industry standards.

Conclusion: Monel 400 tube fittings offer unmatched performance, durability, and corrosion resistance in demanding environments. Their ability to withstand corrosive media, high strength, and versatility make them a preferred choice in various industries. By understanding the properties, advantages, and applications of Monel 400 tube fittings, you can make informed decisions and ensure the efficiency and longevity of your fluid and gas transfer systems.

Equivalent Grades for Monel Tube Fittings

Equivalent Grades for Monel Tube Fittings – Chart form

Price List of Monel Tube Fittings

Tech Tubes & Fittings also provided standard pricelist on demand by the client. However, this is subject to market fluctuations, if there are fluctuations in prices we abstain.

Monel 400 Tube Fittings: Superior Corrosion Resistance and Reliability for Demanding Applications

Monel 400 Tube Fittings: Superior Corrosion Resistance and Reliability for Demanding Applications

Introduction:

In applications where corrosion resistance and reliability are of utmost importance, Monel 400 tube fittings stand out as a superior choice. Crafted from Monel 400—a nickel-copper alloy known for its exceptional properties—these specialized fittings offer robust connections in critical systems. This comprehensive guide explores the remarkable features and advantages of Monel 400 tube fittings, shedding light on their applications, benefits, and considerations. By understanding the unique characteristics of Monel 400, you can make informed decisions when selecting tube fittings for your specific requirements.

- Unmatched Corrosion Resistance:

Monel 400 tube fittings exhibit unparalleled corrosion resistance, making them suitable for a wide range of environments. The alloy's composition, primarily consisting of nickel and copper, provides excellent resistance to corrosive substances, including seawater, acids, alkaline solutions, and industrial chemicals. This resistance ensures the longevity and integrity of tube fittings, even in highly corrosive applications. By utilizing Monel 400 tube fittings, industries can achieve reliable and leak-free connections that withstand harsh conditions.

- High Strength and Durability:

Monel 400 possesses high strength and durability, making it ideal for demanding applications. The alloy maintains its mechanical properties over a wide temperature range, allowing it to perform reliably in extreme conditions. Monel 400 tube fittings exhibit excellent resistance to stress corrosion cracking and offer superior tensile and yield strength. This strength and durability ensure the longevity and integrity of tube connections, minimizing the risk of leaks and failures in critical systems.

- Heat and Pressure Resistance:

Monel 400 tube fittings excel in high-temperature and high-pressure environments. The alloy maintains its mechanical and corrosion resistance properties even at elevated temperatures, making it suitable for applications involving heat exchangers, chemical processing, and oil refining. Additionally, Monel 400 can withstand high-pressure conditions, offering reliable performance and safety in demanding operational settings.

- Compatibility with Various Media:

Monel 400 tube fittings exhibit excellent compatibility with a wide range of media, including corrosive fluids, gases, and seawater. This compatibility makes them valuable in industries such as marine, oil and gas, chemical processing, and petrochemicals. Whether transporting corrosive liquids or handling aggressive chemicals, Monel 400 tube fittings provide a reliable and durable solution, ensuring the integrity of fluid systems.

Monel 400 Tube Fittings: Superior Corrosion Resistance and Reliability for Demanding Applications

Introduction:

In applications where corrosion resistance and reliability are of utmost importance, Monel 400 tube fittings stand out as a superior choice. Crafted from Monel 400—a nickel-copper alloy known for its exceptional properties—these specialized fittings offer robust connections in critical systems. This comprehensive guide explores the remarkable features and advantages of Monel 400 tube fittings, shedding light on their applications, benefits, and considerations. By understanding the unique characteristics of Monel 400, you can make informed decisions when selecting tube fittings for your specific requirements.

- Unmatched Corrosion Resistance:

Monel 400 tube fittings exhibit unparalleled corrosion resistance, making them suitable for a wide range of environments. The alloy's composition, primarily consisting of nickel and copper, provides excellent resistance to corrosive substances, including seawater, acids, alkaline solutions, and industrial chemicals. This resistance ensures the longevity and integrity of tube fittings, even in highly corrosive applications. By utilizing Monel 400 tube fittings, industries can achieve reliable and leak-free connections that withstand harsh conditions.

- High Strength and Durability:

Monel 400 possesses high strength and durability, making it ideal for demanding applications. The alloy maintains its mechanical properties over a wide temperature range, allowing it to perform reliably in extreme conditions. Monel 400 tube fittings exhibit excellent resistance to stress corrosion cracking and offer superior tensile and yield strength. This strength and durability ensure the longevity and integrity of tube connections, minimizing the risk of leaks and failures in critical systems.

- Heat and Pressure Resistance:

Monel 400 tube fittings excel in high-temperature and high-pressure environments. The alloy maintains its mechanical and corrosion resistance properties even at elevated temperatures, making it suitable for applications involving heat exchangers, chemical processing, and oil refining. Additionally, Monel 400 can withstand high-pressure conditions, offering reliable performance and safety in demanding operational settings.

- Compatibility with Various Media:

Monel 400 tube fittings exhibit excellent compatibility with a wide range of media, including corrosive fluids, gases, and seawater. This compatibility makes them valuable in industries such as marine, oil and gas, chemical processing, and petrochemicals. Whether transporting corrosive liquids or handling aggressive chemicals, Monel 400 tube fittings provide a reliable and durable solution, ensuring the integrity of fluid systems.

Conclusion:

Monel 400 tube fittings represent a reliable and corrosion-resistant solution for critical applications. With their unmatched corrosion resistance, high strength, durability, and compatibility with various media, these fittings offer dependable connections that endure demanding environments. Monel 400 tube fittings find applications in industries where reliability, corrosion resistance, and longevity are paramount. By leveraging the exceptional properties of Monel 400, manufacturers and engineers can ensure the integrity and performance of their systems, even in the harshest conditions.

Monel 400 tube fittings represent a reliable and corrosion-resistant solution for critical applications. With their unmatched corrosion resistance, high strength, durability, and compatibility with various media, these fittings offer dependable connections that endure demanding environments. Monel 400 tube fittings find applications in industries where reliability, corrosion resistance, and longevity are paramount. By leveraging the exceptional properties of Monel 400, manufacturers and engineers can ensure the integrity and performance of their systems, even in the harshest conditions.

Stockist of Monel Tube Fittings

LEGAL DISCLAIMER

|

All registered names, trademarks, copyrights and part numbers like Inconel®, Monel®, Hastelloy®, Zeron® etc., remain the property of their respective owners. All use of OEM names, part, model and item numbers are for reference and identification purposes only. TECH TUBES & FITTINGS is not an endorsed reseller or representative of any of above listed Materials / Brands or their respective products. TECH TUBES & FITTINGS products do not infringe on Trade Marks Act 1995 or Copyright Act 1968, and to the best of our knowledge and through investigation we are not in contravention of any current patents |